When classes at Tommy Douglas Collegiate were suspended in late March, Kevin Shmyr looked around the drafting lab and decided to bring a specialized tool home with him in order to continue providing students with opportunities for learning.

When classes at Tommy Douglas Collegiate were suspended in late March, Kevin Shmyr looked around the drafting lab and decided to bring a specialized tool home with him in order to continue providing students with opportunities for learning.

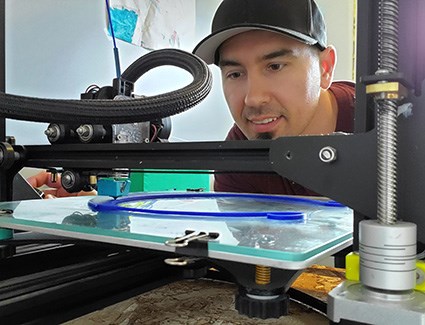

Since then a pair of 3-D printers, two of the four printers that make up the print farm at Tommy Douglas, have become more than just a teaching tool. During the past weeks Shmyr has used them to print visors as part of a project that is providing health-care workers with personal protective equipment (PPE).

"We use our printers regularly with our drafting class," he said. "We are able to physically create models or shapes including student projects and designs that they are able print. I thought it would be good to have the printer at home to be able to make demonstration models and print student designs."

During the early days of the COVID-19 pandemic there was significant concern about a shortage of PPE for health-care workers who may be caring for patients. That concern saw innovators, both locally and worldwide, look for ways they could use technology to address the need.

"I started looking into it and I found there had been a lot of design experimentation," Shmyr said. "There wasn't one official product that was designated as exactly what hospitals want or need but instead there were various prototypes."

So far, he has supplied 38 visors to staff at Melfort Hospital. The clear plastic shields that mount on the 3-D-printed visors are supplied by Bourgault Industries, located in the town of St. Brieux near Melfort, which came on board to support health-care staff in its region. The goal is to produce 75 visor-shield combinations, enough so every staff member who needs one can have their own.

Shmyr made initial contact with a friend who is a manager at the Melfort Hospital to say he had access to a 3-D printer and ask if there was anything staff required. His contact said face shields were needed because the ones usually used by staff could not be sanitized for reuse due to the foam padding that was part of the visor.

Shmyr investigated designs for visors, the band that wraps around the users' head upon which face shields are mounted. He looked at one created by a local printing firm and sourced other designs online to produce prototypes for testing. From there he used feedback received from health workers to finalize his own version.

"I took what I assumed to be the best of each design and made my own based on the feedback I received. Most 3-D files are shared in a way that does not allow you edit someone else's file. This meant that I could use ideas from the existing prototypes, but in order to make modifications I would have to design my own file," he explained.

"It took quite a few different design attempts to make something that fits comfortably on a variety of head shapes and sizes when using a solid plastic as your material. We hope these ones can be used without padding. We had someone try them for a few hours and received positive feedback. Creating head wear that is a universal fit and comfortable is a challenge in itself, while still ensuring that it is supporting a shield properly."

"It took quite a few different design attempts to make something that fits comfortably on a variety of head shapes and sizes when using a solid plastic as your material. We hope these ones can be used without padding. We had someone try them for a few hours and received positive feedback. Creating head wear that is a universal fit and comfortable is a challenge in itself, while still ensuring that it is supporting a shield properly."

His visor design has three contact points for mounting the shield. To ensure consistent spacing, Shmyr referenced a simple piece of technology every teacher is familiar with.

"I spaced the mounting points out to the distance of a three-hole punch unit," he said. "It's a standard distance to allow a simpler shield production process. This allows the shield material to be made in another location, and increase the likelihood of the shield and visor fitting together properly"

While he has ready access to the material needed to print the visors, there were challenges in sourcing other materials. His original design used sewing elastic at the back to ensure a tight, custom fit for users, but realization that the supply of sewing materials might dry up led Shmyr to another low-tech solution.

"The visor wraps around the back of the head and a rubber band is used to tension it. The only part of shield and visor that can't be sanitized, is the rubber band," he said.

Sourcing plastic for the shield was another concern but working with contacts in Melfort led him to Bourgault Industries, which had the appropriate material and was willing to produce the shields.

Sourcing plastic for the shield was another concern but working with contacts in Melfort led him to Bourgault Industries, which had the appropriate material and was willing to produce the shields.

Throughout the process Shmyr has continued teaching his students. He updates them on the progress of his personal project and uses it as an example of how small-scale design and innovation using the tools and technology available to students can have a big impact in helping others.

"I have been sharing this with my drafting students and they are excited about it," he said. "When creating custom design or small quantities of objects 3-D printing can be incredibly useful.

"Right now, our manufacturing sector can't keep up to the personal protective equipment needs. I've had our senior drafting students researching what types of things people are doing in the design world to innovate while things are changing around us quite rapidly. The current assignment that my senior drafting students are working on is to come up with their own design of an object that can help people during this time. They could try to create their own piece of PPE or create an object that allows people to avoid common public touch points.

While learning is continuing from a distance, Shmyr misses opportunities to connect face-to-face with students as they design and create. He is working on a process where students will be able to submit their designs for him to print and then provide a safe way to transfer the printed object back to the student, but it won't replicate the regular classroom experience.

"Students and teachers do face limitations in these circumstances. Luckily the area of drafting and design is largely computer based, but students are still missing out on a lot of the connection of bringing their 3-D designed models to life by learning all the ins and outs of operating a 3-D printer," he said, noting the benefits of students being able to hold and examine a physical prototype to help refine their design.

"I think that all teachers are finding this time challenging. We miss being able to interact with our students face to face. In the meantime, we are just looking to support our students in any way we can and facilitate their learning from a distance."